+86 15820465158

kevin@kayoumold.com

In daily life, how to distinguish between good and bad plastic molds is indeed a problem, especially when remotely controlling market transactions on the Internet.

After the product design plan is initially determined, there are three benefits to contact with the mold manufacturer in advance

First, in the production and processing of plastic molds, especially in the preparation design stage, the first thing to determine here is what kind of injection molded parts we want to choose before accepting the design.

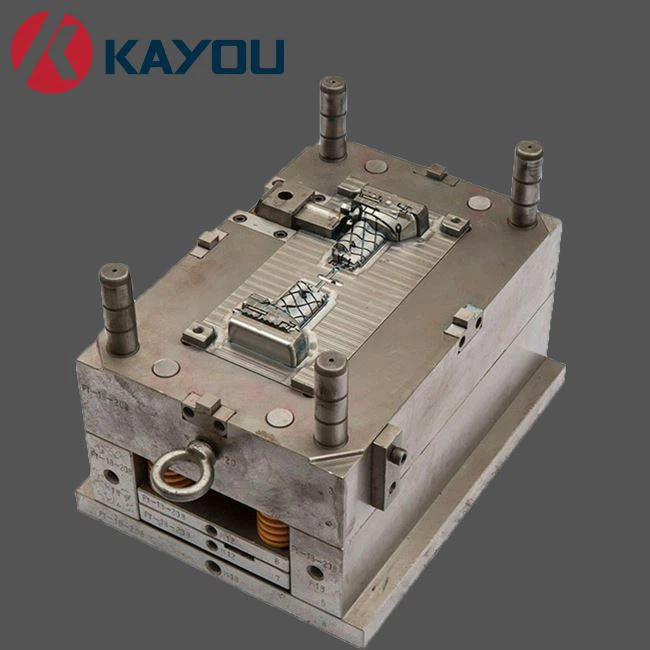

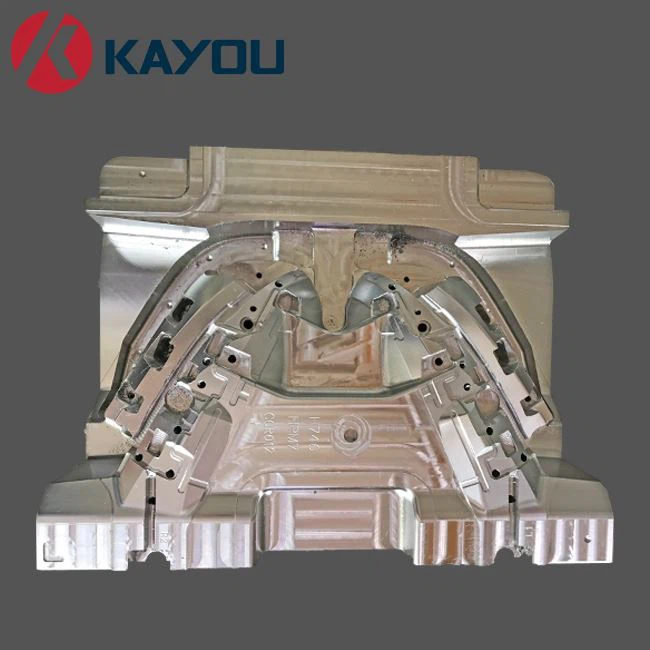

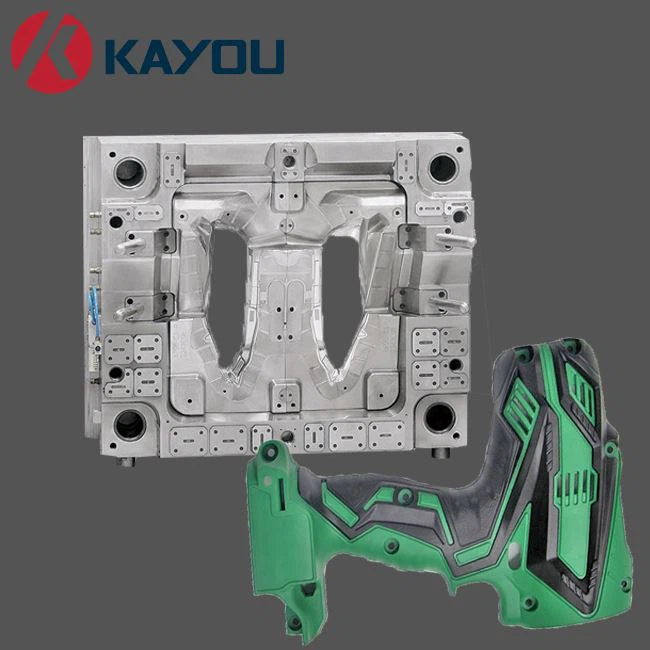

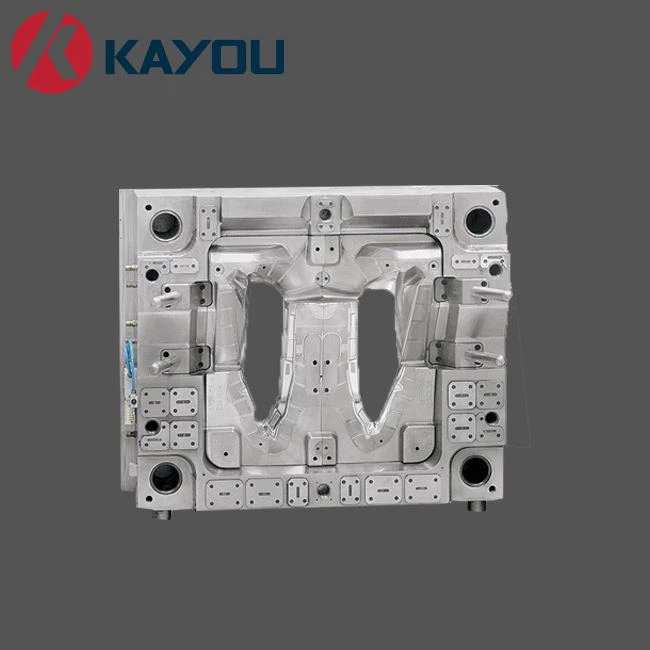

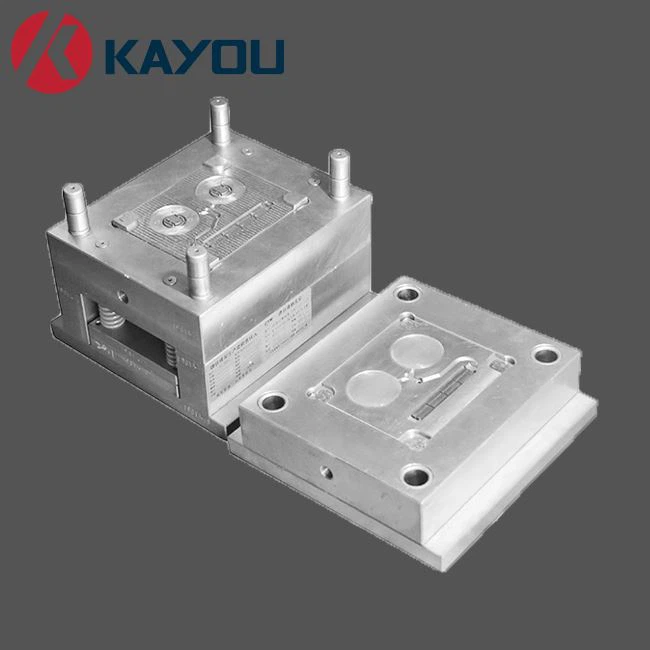

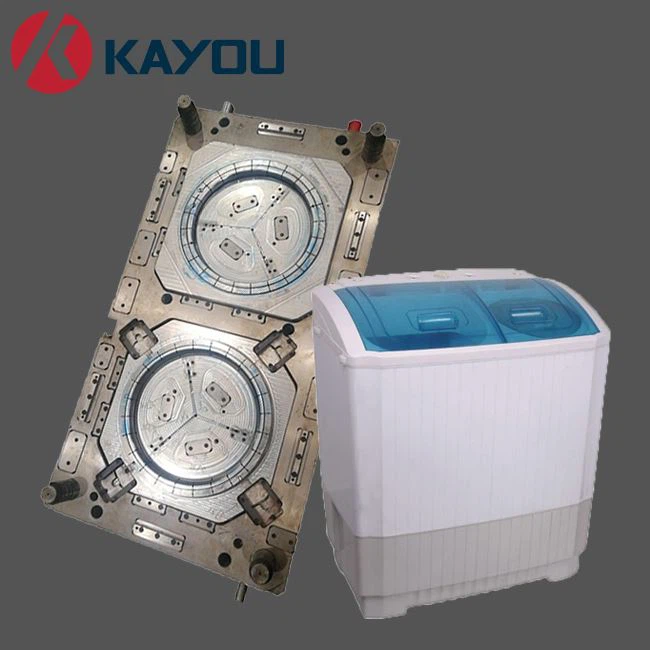

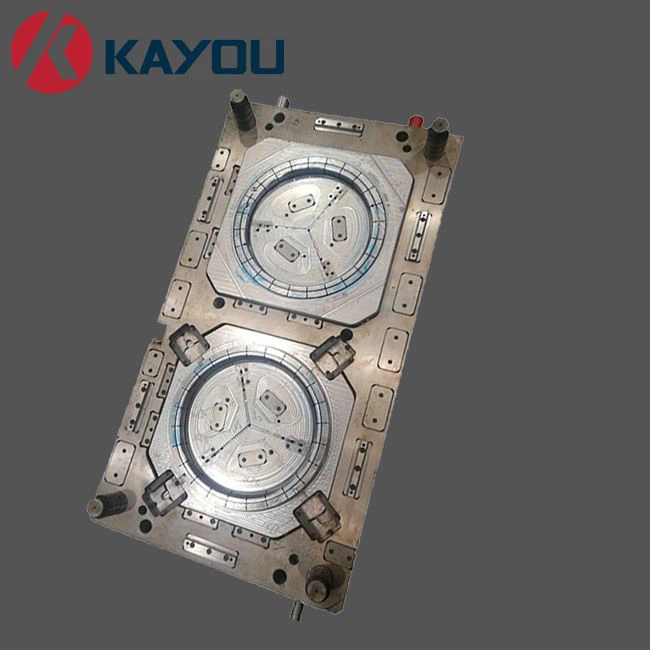

Plastic mold is a tool for consuming plastic products. It is partially composed of several groups of parts, and there is a molding cavity in this combination.

First of all, the materials used for plastic mold manufacturing should be easy to process.

When buying various plastic toy live products in the market, you will find that most of the toys and plastic products have relatively smooth surfaces.

Plastic injection molding is a processing method for mass production of some unorganized parts.

With the advent of high-speed molding machinery, the production speed of plastic products has continued to increase.

Before the mold industry in the 1990s, due to the lack of popularization of CNC machining equipment

The gap of the die is related to the type and thickness of the stamping material. Unreasonable clearance will cause the following problems