+86 15820465158

kevin@kayoumold.com

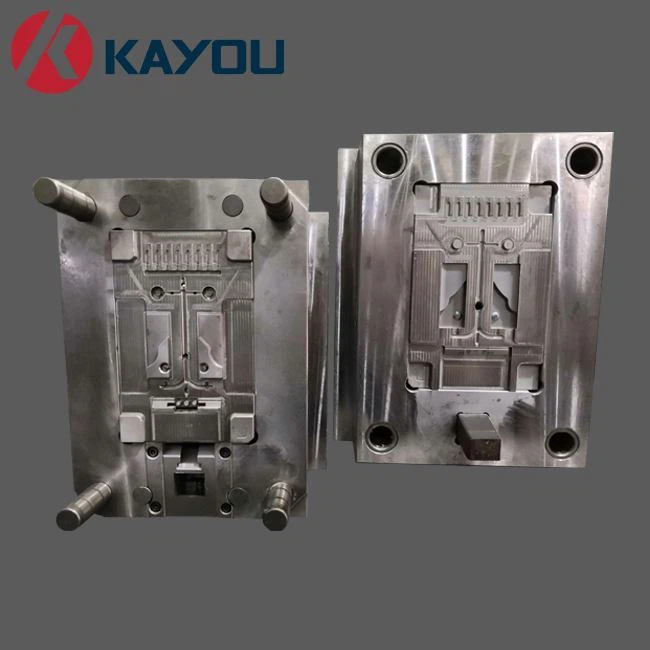

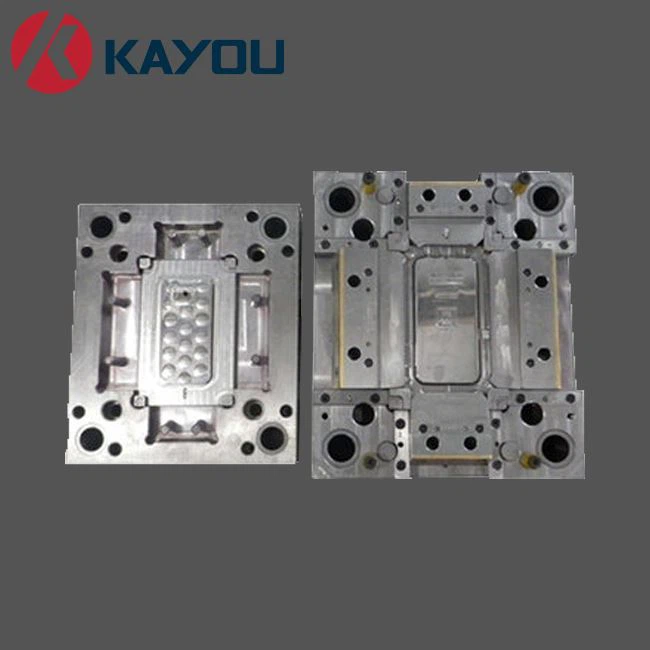

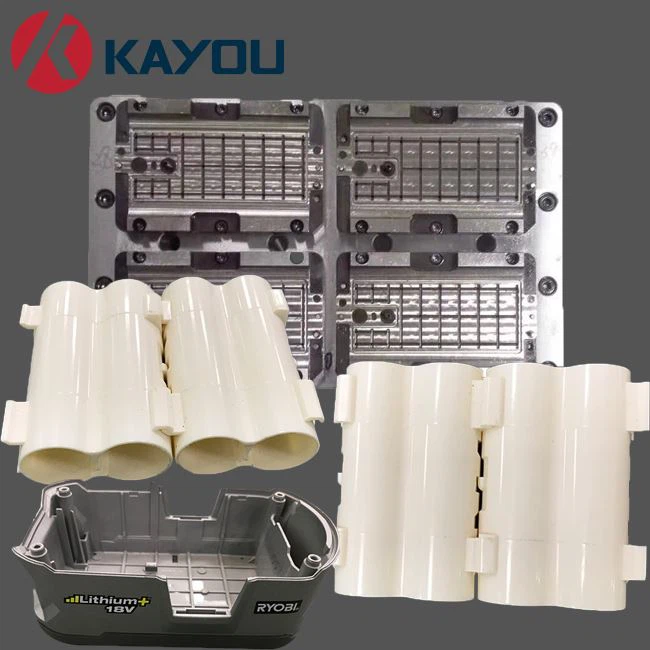

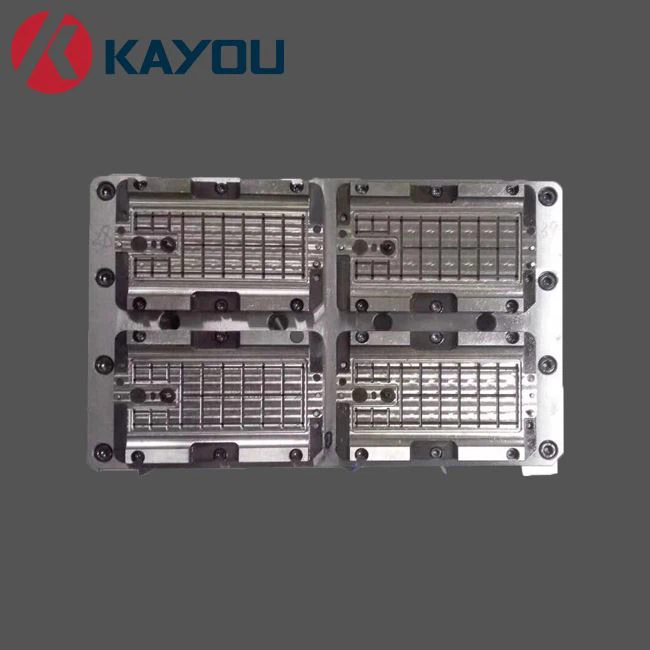

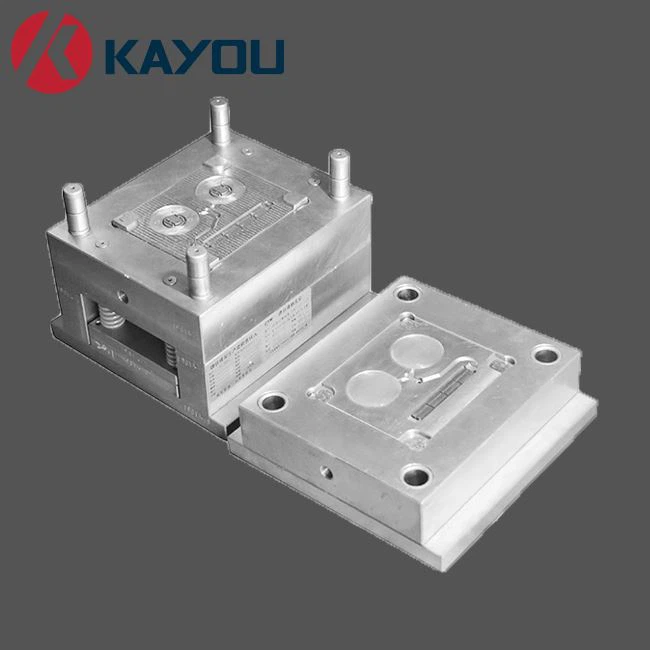

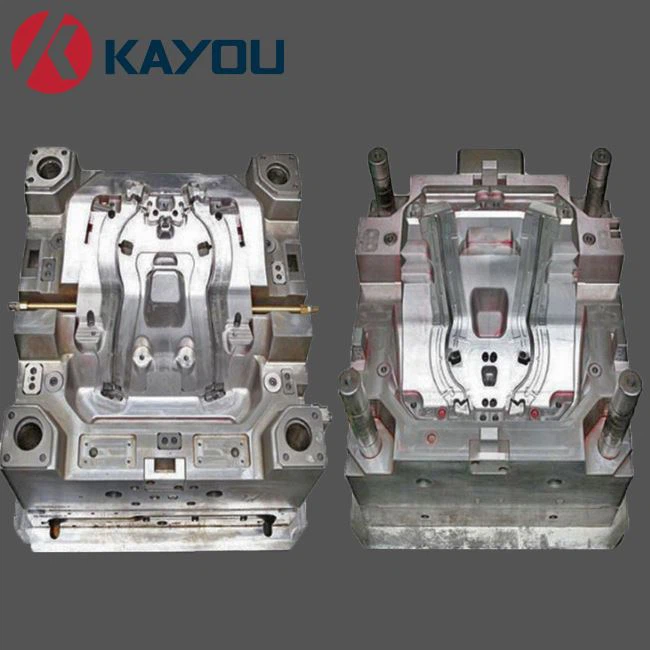

Do you know what is injection moulding? Injection moulding is a manufacturing process to produce parts for products. Such as, when you need to make a power bank, you have to make the cover and house for it at first. These plastic parts can be made by injection moulding with the mold. Then how...

In the process of plastic mold processing, if various parameters cannot be well controlled, plastic products will easily shrink after shaping, which will affect the accuracy of plastic processing.

The margin of water transportation and the margin of product material level are generally not less than 10MM, and the design should be between 10MM-12MM as much as possible; the alloy mold is generally 25MM

Mold cleaning is a key process in mold maintenance and a bottleneck restricting mold maintenance.

In the production of plastics, there are often many factors that affect the quality of the product.

Service life: Under the premise of ensuring product quality, the number of work cycles that the mold can complete or the number of parts produced.

Reasonably use cooling lubricating fluid to play the three roles of cooling, cleaning and lubrication, keep cooling and lubrication clean, control the grinding heat within the allowable range, and prevent thermal deformation of the workpiece.

Plastic injection molding is a processing method for mass production of some unorganized parts.

Plastic mold, an abbreviation for a combined plastic mold used for compression molding, extrusion, injection, blow molding and low foam molding