+86 15820465158

kevin@kayoumold.com

What is the Key points to ensure the quality of injection mold? In recent years, the sales of mold testing equipment have been increasing. It can be seen that the injection mold market has more and more stringent requirements for quality improvement, which will continue to improve the quality of...

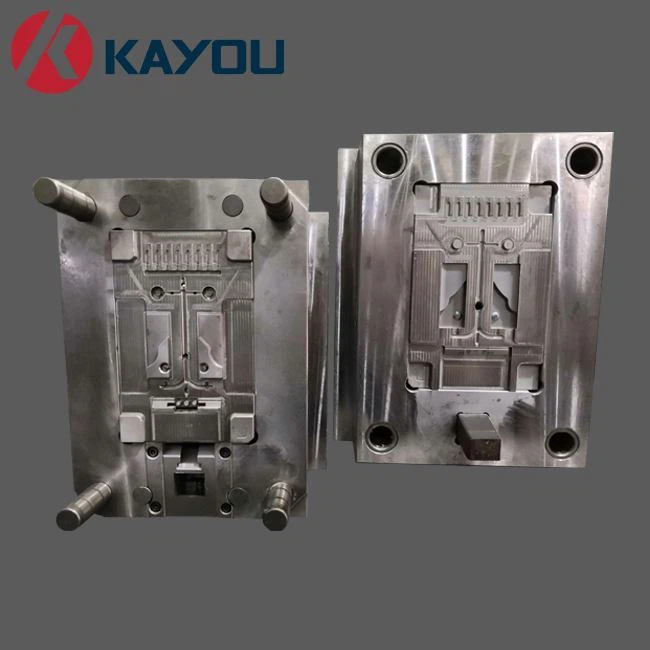

What are the main considerations in designing a standard injection mold? In general, a standard injection mold design will start from the design of the plastic part. And the main job on designing a good plastic part are as below. 1, Design and analysis of the plastic part to avoid defects...

How to do review on 3d drawing of plastic parts for injection mold? It is very important job to do a nice review on the 3d drawings before quote price for mold. The following points should be noted when do review on drawings of platic parts for mold. The material, dimension, structure of the...

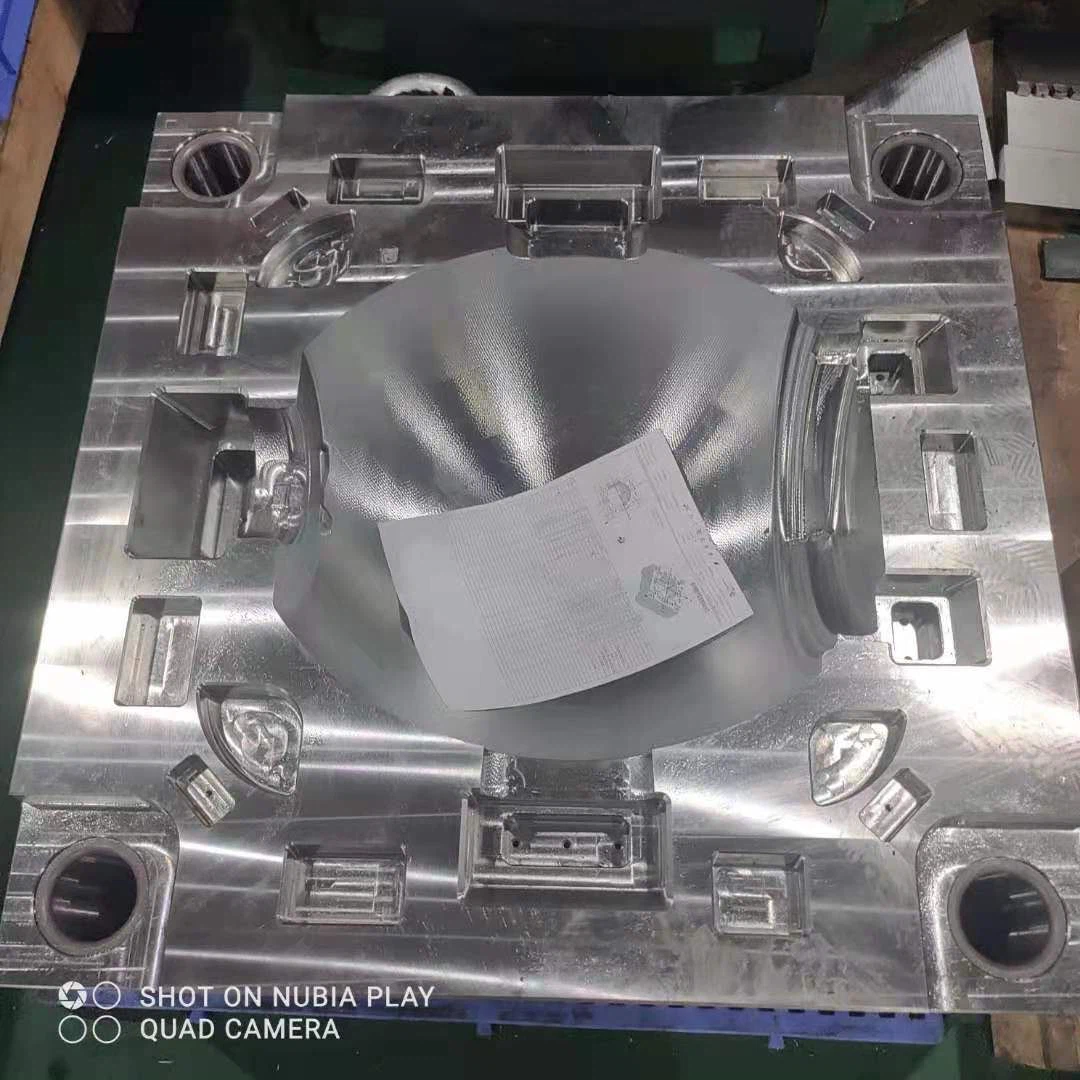

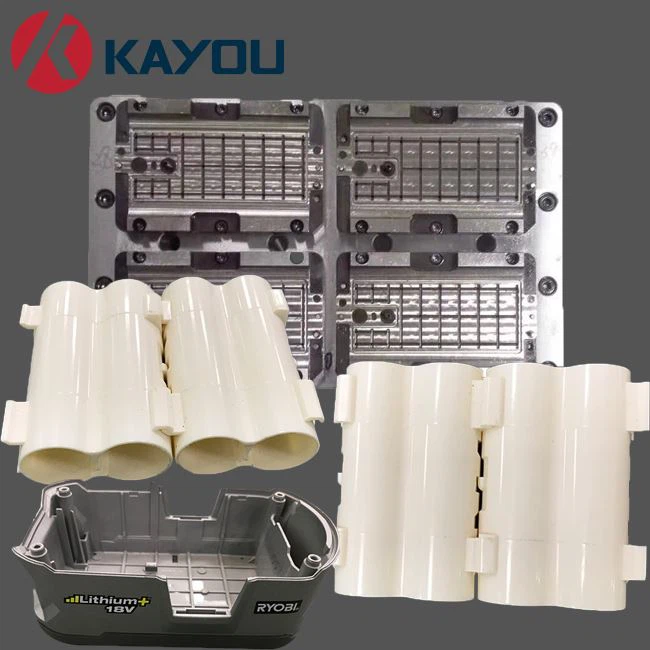

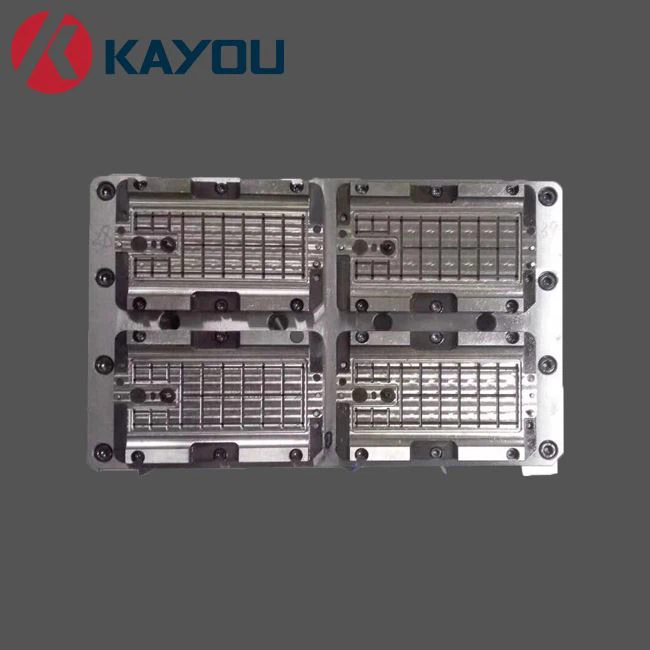

Do you know what is injection moulding? Injection moulding is a manufacturing process to produce parts for products. Such as, when you need to make a power bank, you have to make the cover and house for it at first. These plastic parts can be made by injection moulding with the mold. Then how...

In the process of plastic mold processing, if various parameters cannot be well controlled, plastic products will easily shrink after shaping, which will affect the accuracy of plastic processing.

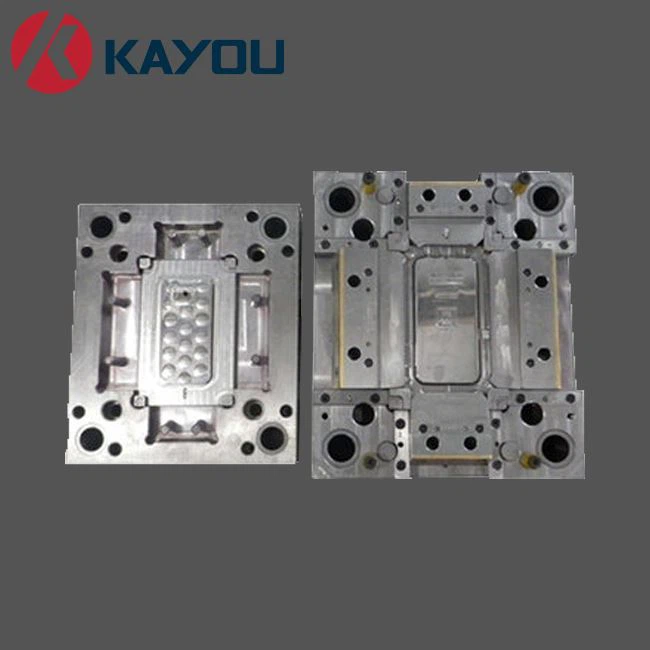

The margin of water transportation and the margin of product material level are generally not less than 10MM, and the design should be between 10MM-12MM as much as possible; the alloy mold is generally 25MM

Mold cleaning is a key process in mold maintenance and a bottleneck restricting mold maintenance.

In the production of plastics, there are often many factors that affect the quality of the product.

Service life: Under the premise of ensuring product quality, the number of work cycles that the mold can complete or the number of parts produced.