5G Internet Junction Box Plastic Injection Mould

Top rate chinese factory manufacture service for 5G internet junction box plastic injection mould 1, Basic introduction of plastic injection mould An injection mold consists of two halves that are forced together to form a cavity in the shape of the part to be produced. Hot liquid plastic is...

Top rate chinese factory manufacture service for 5G internet junction box plastic injection mould

1, Basic introduction of plastic injection mould

An injection mold consists of two halves that are forced together to form a cavity in the shape of the part to be produced. Hot liquid plastic is then injected at high pressure into this cavity. The high pressure is needed to ensure that the plastic resin fills in every crook and cranny of the mold cavity. Once the plastic has had time to cool, the two halves of the mold are pulled apart, and the part is ejected. Although designing for injection molding can be quite complicated, and the cost of the molds themselves are incredibly expensive, there is one huge reason why injection molding is still used today. No technology can beat injection molding when it comes to producing millions of identical copies of a part at an incredibly low price.

2, Product introduction of 5G internet junction box

5G is the next generation of mobile connectivity which succeeds the current 4G and older 3G systems. It stands for fifth generation and should deliver faster speeds, more reliable connections and more consistent ones too. Currently 4G is capable of speeds between 10 and 20Mbps in the real world, while Vodafone claims speeds of up to 225Mbps with its 4G+. But that pales in comparison with 5G, which is capable of connections up to 100 times faster than 4G, currently achieving connection speeds of over 1,000Mbps. And internet junction box is the base which to support 5g internet.

3, Product parameter of 5G internet junction box plastic injection mould

| Name | plastic injection mold for 5g internet junction box shell or case |

|

Mold Type |

injection mould. |

| Base Material | best quality LKM steel |

| Core and Cavity | nak80, p20, 718, h13, 2344, s136, etc. |

|

Runner |

hot runner or cold runner. |

| Slider | with sliders or without sliders. |

| Treat | surface polish. |

| Life Time | 50000 to 500000shots. |

| Part No. in Unit Shot | 1pcs or more pcs, it depends on how many cavities in the mould. |

| MOQ | 1PCS. |

| Lead Time | 30days after deposit payment received. |

4, Product parameter of 5G internet junction box

| Name | 5G internet junction box. |

| Type | plastic shell / plastic case / plastic cover / plastic parts. |

| Forming type | injection moulding. |

| Material | plastic material like, ABS, PC, PVC, or as customer requirements. |

| Color | single color or multi color as customer requirements. |

| Thickness | any thickness as customer requirments. |

| Size | any size as customer requirements. |

| Finish | polish treatment. |

| Custom | We accept oem or odm custom order. |

| MOQ | 5000PCS. |

| Lead Time | 30days |

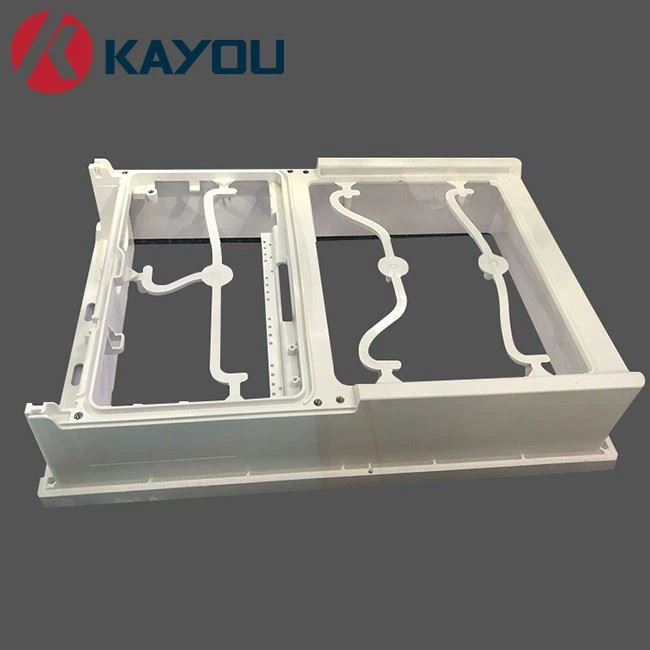

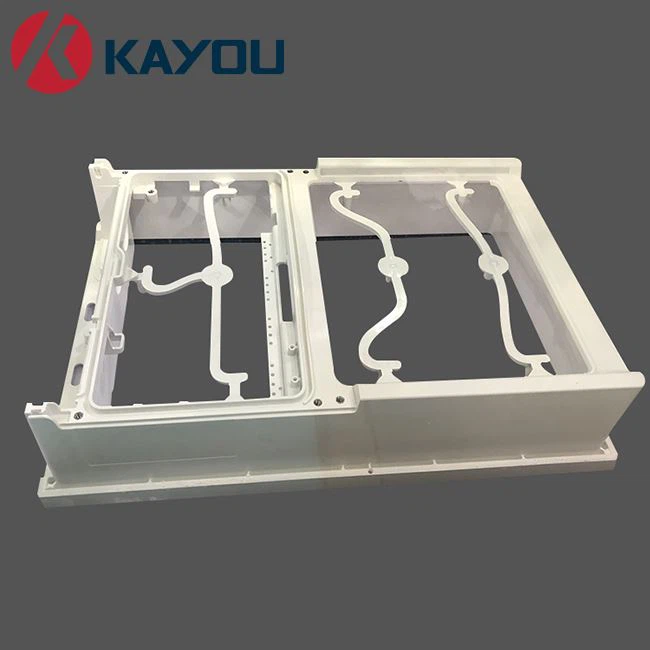

5, Product show for 5G internet junction box

6, Advantage on 5G internet junction box plastic injection mould

In 2019, We have made a plastic injection mold which is for united state 5g internet junction box. It is a very famous internet company in united state. They had the new project on 5g internet. They were going to renew the internet service for unite state market. And with 5g internet, they can increase too much on the internet speed. They had big requirements of 5g internet box to support them. And they placed the mold for the internet junction box to kayou factory. When we did a sample trial on the injection mold, They were very satisfied on our mold and moulding quality. After they received our sample, they placed the bulk production order of internet box directly. They arranged us to produce the moulded plastic parts of the internet box. We produced over 100000pcs and shipped to the unite state client. And we have got the highly comments from our clients on the quality products. And we are confident we will have more good cooperation if they get new project on plastics.

7, Packaging and shipping of plastic injection mould

All molds will be assembled in one set and set in good position inside of wood box. And all boxes are firmly sealed. They can be no problem to shipped by sea, by air or by train. You can choose the shipping method according your requirements. We can also help you to do shipping if you donot want to arrange shipping by yourself.

8, Packaging and shipping of 5G internet junction box

All separated plastic parts will be packed in polybag and then put them into carton box. And all boxes are firmly sealed. They can be no problem to shipped by sea, by air or by train. You can choose the shipping method according your requirements. We can also help you to do shipping if you donot want to arrange shipping by yourself.

9, Satisfied Factory Sale Service

Kayou works as a professional mold and moulding factory, has rich experience on design and manufacture in the global.

Kayou has the good sale teams to give you the nice sale service.

Kayou has the good technical team to support you in the sale and after sale service.

Kayou always put your cost, your effeciency and your time in our top consideration.

10, FAQ for mould and moulding service

(1), Q: Do you have experience in 5g internet box mould?

A: Yes, we have made it for USA client in 2019.

(2), Q: Do you have your own factory?

A: Yes, Kayou is our own mold factory.

(3), Q: Do you support moulding service for 5g internet box plastics?

A: Yes, kayou factory have the moulding machines to support productions of your plastics parts.

(4), Q: What is the prompt sample time for 5g internet box plastics?

A: It depends the design. The soonest, we can make sample ready to ship within 7days.