Automotive Car Interior Trim Shell Plastic Mould

Professional customize manufacturer for high precision auto parts automotive car interior shell plastics mould

Professional customize manufacturer for high precision auto parts automotive car interior shell plastics mould

1, Basic principle of plastic injection moulding

Plastic injection moulding is the main method to build varieties of car parts. The three main elements of plastic injection molding are "plastic materials", "plastic molds" and "plastic injection machines". These three elements will be subdivided into many different categories due to different manufacturing needs, such as plastic materials can be subdivided into crystalline and non-crystalline; plastic molds can be subdivided into two-plate mold, three-plate mold, and hot-runner mold; plastic injection machine can be subdivided into hydraulic crankshaft type, two-plate direct-pressure type, and all-electric type. Before the manufacturing process of injection molding, let's briefly understand the structure of the injection machine, the barrel: the location where the raw materials are stored, and the material tube: that is, the channel from the material to the mold, and the material tube is covered with a "screw", which function is to melt the plastic, mix the chain, and inject a certain amount of plastic into the mold. The mold: It is like a model of chocolate. The raw materials are injected into it to shape a product with a specific shape. There is a "thimble" on the mold. The main function is to push the product out of the mold, that is, to separate the product from the mold. This is the basic working principle of plastic injection moulding.

2, Product introduction of automotive car mould

Auto car plastic parts mould are the high precision injection mould. They have very high accuracy requirements on the mould design and moulding quality. As a professional China Auto part mould manufacturers and Auto parts moulding suppliers, Shenzhen Kayou Plastic Injection Mould Co., Ltd has the key technology of R&D, design, manufacturing and injection molding of precision plastic moulds,Through over 20 years of hard work and development, the company has continuously increased R&D investment and developed new products, and actively applied advanced information management technologies and tools such as ERP, and strove to achieve integration with international standards to enhance the core competitiveness of enterprises. our factory can simultaneously produce moulds that meet different standards such as HASCO, DME and MISUMI. We has now established a high reputation in the field of automotive air-conditioning moulds. More than 80% wholesale plastic Auto part moulds are exported to more than 30 countries including Germany, the United States and Europe. The company will continue to innovate and improve to build a well-known mould company at home and abroad! We are very happy to send you our quotation if you have project on automotive car mould.

3, Product parameter of automotive car interior trim shell mould

| Name | car parts mould. |

|

Mold Type |

injection mould. |

| Base Material | LKM, or other material which you requested. |

| Core and Cavity | nak80, p20, 718, h13, etc. |

|

Runner |

Hot runner or cold runner. |

| Slider | Need or no need, depends on you. |

| Treat | high quality polished. |

| Life Time | 50000-1000000shots |

| Part No. in Unit Shot | 1pcs or 2 pcs, or as you want. |

| MOQ | 1sets. no limit. |

| Lead Time | 35days. |

4, Product parameter of automotive car interior trim shell

| Name |

auto interior parts shells. |

| Type | moulding type |

| Forming type | injection moulding type |

| Material | PC, auto PC, or as you liked. |

| Color | customized. |

| Thickness | as you designed. |

| Size | as you designed. |

| Finish | highlight polished. |

| Custom | support OEM & ODM customize. |

| MOQ | 5000pcs. |

| Lead Time | 30days. |

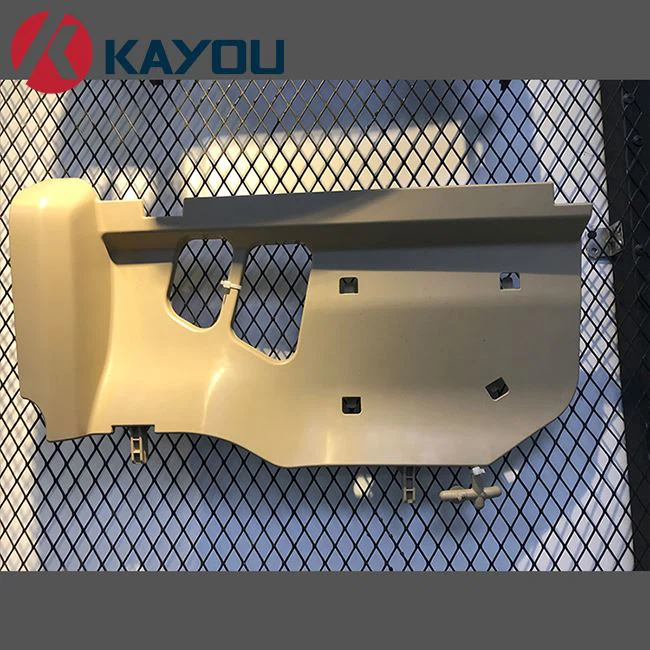

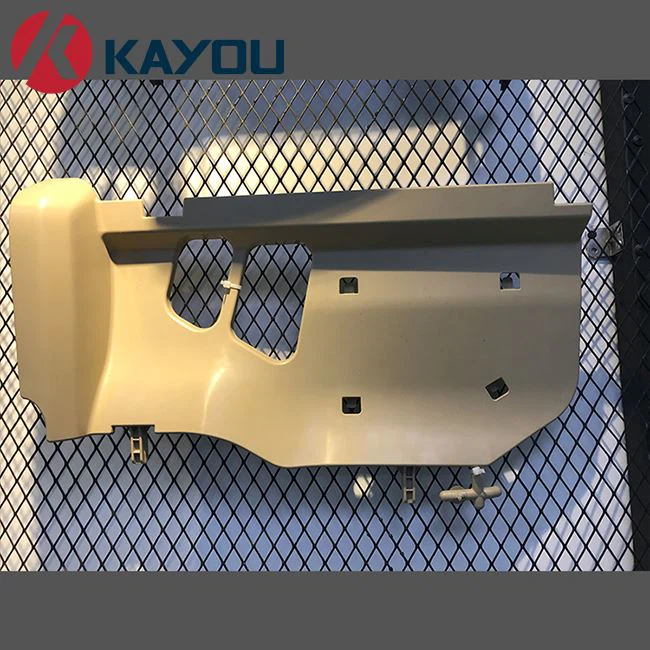

5, Product show for automotive car interior trim shell

6, Advantage on automotive car interior trim shell mould

We are the expert on plastic injection mould, especial on auto car plastic mould. We have cooperated with BMW manufacturer on mould and moulding for over 10years. We have worked with BMW manufacturer on many different types of moulds, like car lamp moulds, car door moulds, car monitor pannel mold, etc.

7, Packaging and shipping of plastic injection mould

For packaging, 1set of mould will be assembled and put inside of high quality wood box. After checking, it will be tightly sealed. Finally we will put the marks on the surface.

For shipping, we sugguest customer arrange shipping cost himself, but also we can help customer arrange shipping.

8, Packaging and shipping of automotive car interior trim shell

For packaging, 10pcs of car parts will be put inside of polybags. 10pcs polybags will be put inside of carton box. After checking, it will be tightly sealed. Finally we will put the marks on the surface.

For shipping, we sugguest customer arrange shipping cost himself, but also we can help customer arrange shipping.

9, Satisfied Factory Sale Service

One stop service for plastic products and plastic mould.

Professional auto car mould engineer team service.

Free charges of aftersale service.

Quick quotation service.

Quick lead time service.

Quick sample service.

10, FAQ for mould and moulding service

(1), Q: How soon can i get the quotation?

A: Quick quotation can be within 3hours.

(2), Q: Do you support customize plastics according my product designing drawings?

A: Yes, we support it.

(3), Q: What is youir MOQ for plastics?

A: It depends on what kind of plastic product you want. Normally it is 5000pcs.

(4), Q: How long time is your lead time?

A: For mold making, it will need around 30days. For plastics,It will need around 30days.