+86 15820465158

kevin@kayoumold.com

The gate of the plastic mold is the channel connecting the main runner (or branch runner) and the cavity.

Reasonable application of cooling lubricating fluid to play the role of cooling, washing and lubrication, to maintain cooling and lubrication clean

When the plastic mold factory is processing, if there is deformation, cracks, skin oxidation, decarburization, etc., it means that the mold has failed.

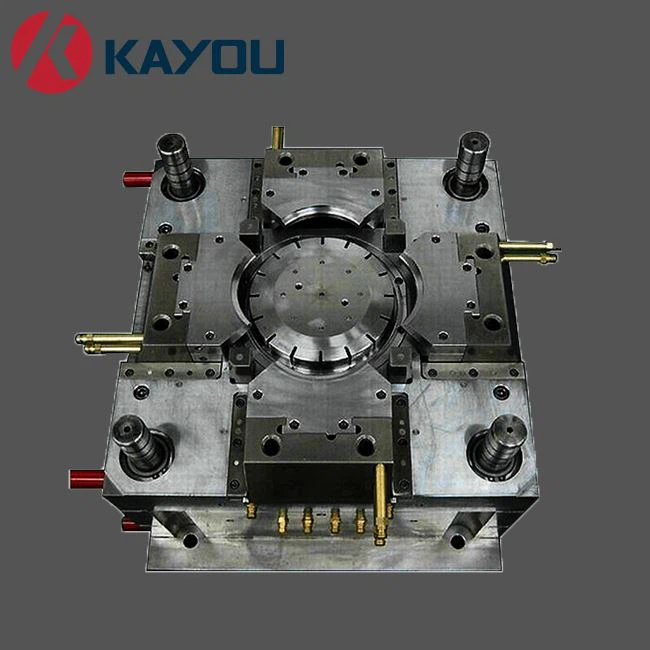

Plastic mold processing molds are mainly composed of pouring system, temperature adjustment system, molding parts and structural parts.

The service life of the mold cleaning thimble is one year. If it exceeds a one-year cycle, the thimble will become dirty on the surface due to gas accumulation and mold impurities.

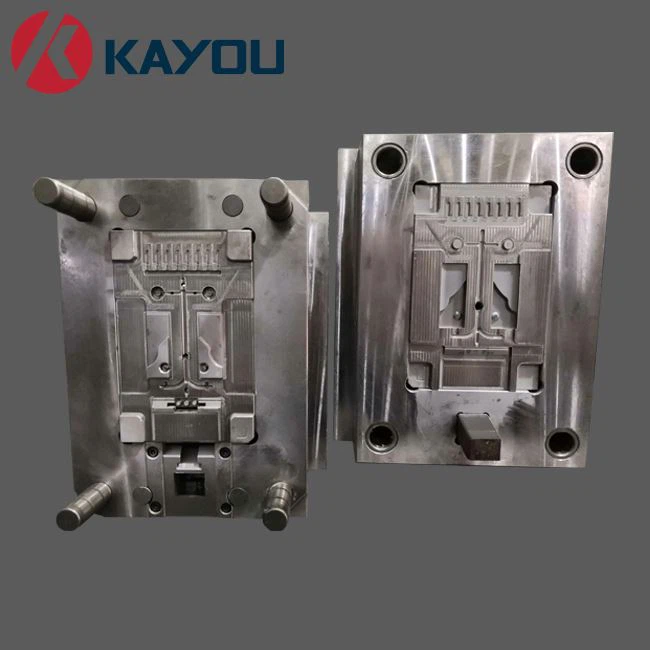

Plastic mold processing refers to the processing of plastic molding and plastic blanking tools. It consists of an upper mold and a lower mold.

The so-called parting surface is the surface where the mold is opened to take out the product. The selection of parting surface is also the first step of mold design.

The first thing to do is to carry out on-site inspections, verifications, and evaluations of the verification management system for the outsourcing production and processing enterprises, and make a work summary.

Hot runner mold: The structure of this type of mold is roughly the same as that of the nozzle.

The first thing to look at is the mold material. Many customers know that the mold material must be determined with the manufacturer before placing the mold order.