Experience in mold opening for air purifier

This is mainly aimed at people who have product experience, and are not ready to enter the industry without knowing anything.

First of all, to prepare to design the product drawings, can be designed in accordance with their own ideas, can also refer to others' sample modification (this way is more popular in China)

Then go to do a hand piece, also known as rapid prototyping, this is based on drawing on the basis of perfect design, or a waste of money, according to the drawings to make rapid prototyping can only be used for shape reference, reference assembly, as well as functional testing, with the real mould still have differences, because mould also consider draft, whether good glue, whether can produce cosmetic defects, These are all things that rapid prototyping doesn't need to consider.

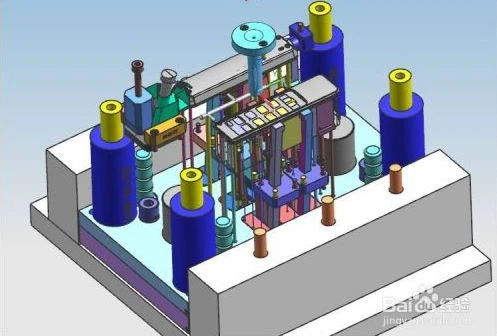

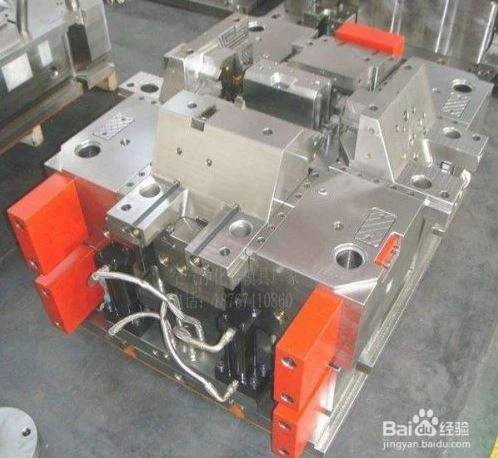

Finally, after the completion of the rapid prototyping think already conform to your request, you can go to open mold, advice final design drawings and the samples are for each other, their appearance requirements, into the glue demands, die life tell each other, let the other side to make a products according to the requirement analysis and mold design analysis, image is one of the finished product of mould cavity.

If you can follow the above requirements, your product will not be far from success. If you do not know anything about your product, or what is the glue inlet of the mold, it is very dangerous, because some structures on the mold will directly affect the product in the end, and this can not be changed in the later stage!!