Plastic Lid Injection Mould

High precision injection mold for plastic lid. 20years' Plastic Injection Mould Maker and Moulded Plastic Parts Factory. Welcome to contact us for more details.

Do you have any new projects and new design?

Why not send the 2D/3D drawing via our email to test our price first?

And we will get back to you regarding the parts feasibility and more suggestion to your detail requirement.

Pls contact us now!

High precision injection mold for plastic lid manufacturer in Shenzhen of China

1,The introudction of injection molding for plastic lid

In our daily life, we almost touch plastic lids everyday, like drinking water bottle lid, garbage bucket lid, electric cooker lid, and so on. They are all formed by injection molding. Injection molding is the process for production of plastic parts. Factory eject heated liquid plastic, maybe ABS, or maybe pp, depend on the product feature, into the cavity of two parts of mold, finally the plastic part get colded and get formed. This is the moulded plastic part.

2, Plastic material to injection moulding

Different plastic material may have different quality, so if you want to produce the good quality plastic parts, and get the good quality finish product, it is very important to choose the good quality level plastic material, it is not vise to cut the cost on plastic material, because even we make the good quality mold for you, your factory still cannot produce the good quality parts because you use the low quality of plastic material, maybe color will get lost fast, maybe size get shrinked. Because the low quality material has low stable on color and size. And it will be heated and cooled during the injection moulding process. It cannot give the good performance on the finish because it is low quality level material.

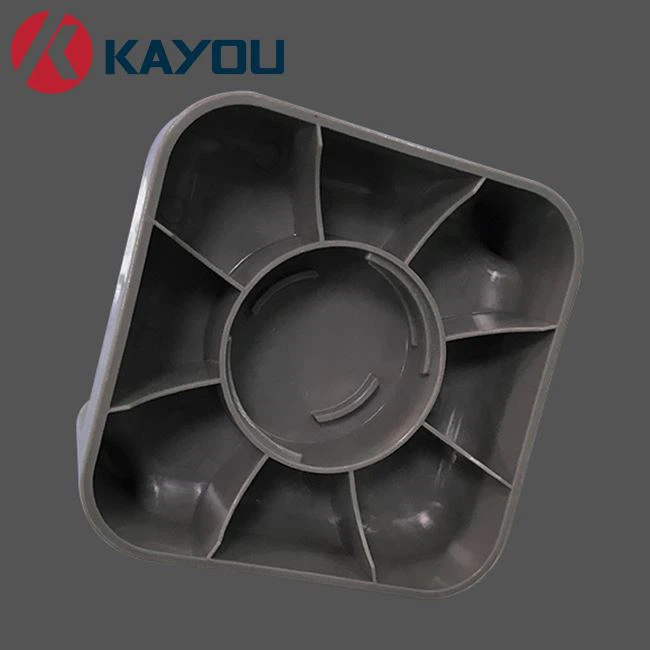

3, The photo show of plastic lid or cap

4, The specifications to plastic lid mold

| Mold Name | plastic lid injection mould |

| Category | home appliance device mold. |

| Type |

plastic injection |

| Ejection Material | plastics. |

| Ejection System | nozzle. |

| Base Material | LKM or upon your requirement. |

| Core and Cavity Material | NAK80 or as you liked. |

|

Cavities Quantity |

single or multi ,etc. |

|

Type of Gating |

subgates. |

|

Runner |

hot runner. |

|

Life Time |

10000 to 300000shots. |

| Deliver Time | 25 to 30days. |

5, The packaging and shipping

Good packaging will be done accordingly different products.

Good packaging will be done to meet strict protection while shipping.

6, FAQ

Q: 1 Are you trading company or manufacturer ?

A: We are factory.

Q: 2 Where is your factory located?

A: Our factory is located in shenzhen, China.

Q: 3. How to go to your factory?

A: You can come to our city by flight, bus or train.

It takes 2 hours by flight from Guangzhou to our city.

It takes 3.5 hours by train from Shanghai to our city.

It takes 1 hour by bullet train from Ningbo to our city.

Q: 4.How about quality control in your factory?

A: We believe "Quality is above everything". We have professional team to control the quality. Our QC team mainly do the following procedures:

A) Design Optimize control

B) Mould steel hardness Inspection

C) Mould assembly Inspection

D) Mould trial report and samples Inspection

E) Final inspection for mould & packing before shipmentIf you have another question, pls feel free to contact us.