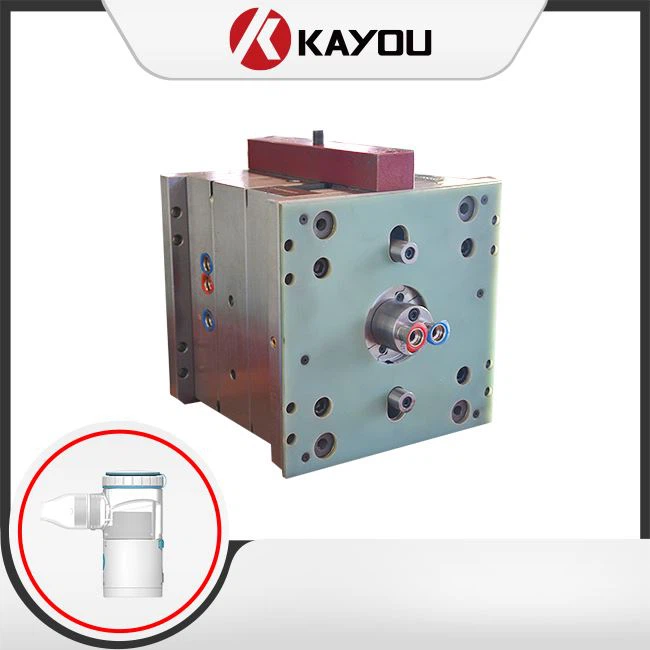

mistorizer injection mould and moulding

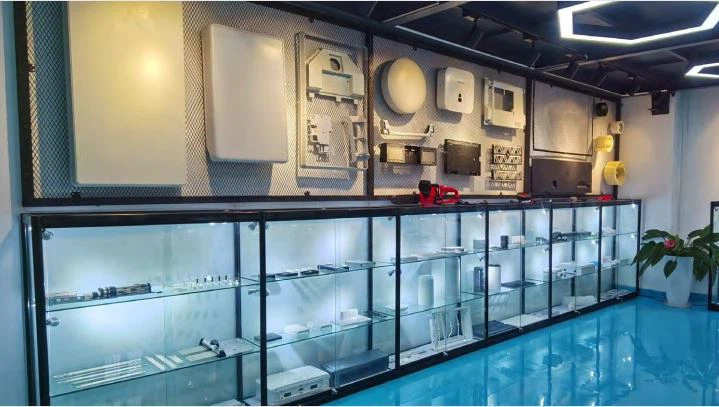

Factory Introduction

KAYOU was founded in early 2002, located in ShenZhen, China.

Main business focus on mould manufacturing and

plastic injection.

Our Advantage:

1. We are a professional OEM manufacturer.

2. We have experienced engineers and quality control team as our strong backing.

3. High quality, competitive price, quick response is our mission.

4. Professional technical support

5. Good delivery time

6. Strict quality control process

7. Cost-Effective

8. ISO/ERP system guarantee

|

Product Name |

mistorizer injection mould and moulding |

|

Core &Cavity Steel |

P20,718H,2738H, H13, NAK80,2316 etc. |

|

Mould base & Standard Component |

DME,HASCO,Self-made etc. |

|

Steel hardness: |

HRC35-38 |

|

Plastic material |

PP,PC,PE,ABS,PVC etc. |

|

Cavity Number |

1*1 |

|

Injection System |

Side Gate,hot gate |

|

Ejector System |

Ejector Pin |

|

Cycle Time |

30-60S |

|

Tooling lead time |

45-60 Days |

|

Mould life |

500,000 Shots |

|

Quality assurance |

ISO9001 |

Our Advantage:

1. We are a professional OEM manufacturer.

2. We have experienced engineers and quality control team as our strong backing.

3. High quality, competitive price, quick response is our mission.

4. Professional technical support

5. Good delivery time

6. Strict quality control process

7. Cost-Effective

8. ISO/ERP system guarantee

|

Product Name |

Home beauty products |

|

Core &Cavity Steel |

P20,718H,2738H, H13, NAK80,2316 etc. |

|

Mould base & Standard Component |

DME,HASCO,Self-made etc. |

|

Steel hardness: |

HRC35-38 |

|

Plastic material |

PP,PC,PE,ABS,PVC etc. |

|

Cavity Number |

1*1 |

|

Injection System |

Side Gate,hot gate |

|

Ejector System |

Ejector Pin |

|

Cycle Time |

30-60S |

|

Tooling lead time |

45-60 Days |

|

Mould life |

500,000 Shots |

|

Quality assurance |

ISO9001 |

QUALITY

DEPARTMENTS

& QUALITY

CONTROL

• Projectors

• microscopes

• CMM

• We checked every insert ,

copper electrode

• We checked dimension for

each samples.

Mould base & Steel

● HASCO DME LKM

● NAK80

● S136

● 718H 738H

● SKD61

● DC51

MOLD MANUFACTURING

Applications

● Automotive

● Household appliance

● Medical

● Electronic Devices

● Commercial Products

● Consumer Products

The Guarantee

● Hot runner 5 years

● Mould 300k-1kk

Injection Moulding

Applications

Automotive Security products

Household appliance

Medical

Electronic Devices

Commercial Products

Consumer Products

ABS

PC

ABS+PC

PP

Nylon

Nylon – Glass Fill

Polycarbonates

Polyethylenes

Process Materials

Plastic injection molding:

Over 18 year of experiences and modernly

equipped machines with clamping force from

50 to 350 tons, provide the manufacture of articles

weighing from a few grams to several kilograms

with different design solutions for automotive

industry and products of mass

Shot Capacity:

from less than a gram, up to 41 ounces per cycle.

Custom Colors:

Custom plastic parts according to your

specifications.